What You Need to Know About 25mm Pillow Block Bearing

The 25mm Pillow Block Bearing is a crucial component in various machinery and equipment, providing essential support and alignment for rotating shafts. As the demand for high-quality bearings continues to rise, the global bearing market is projected to reach approximately $100 billion by 2025, with a significant portion attributed to industrial automation and machinery manufacturing.

The 25mm Pillow Block Bearing, known for its reliability and efficiency, is particularly favored in applications across automotive, aerospace, and heavy machinery sectors. In a recent industry analysis, it was noted that the adoption of advanced materials and manufacturing techniques has significantly enhanced the performance and longevity of pillow block bearings. Understanding the specifications, benefits, and installation tips for the 25mm Pillow Block Bearing is essential for engineers and manufacturers looking to optimize machinery performance and minimize downtime.

Understanding the Importance of 25mm Pillow Block Bearings in Various Applications

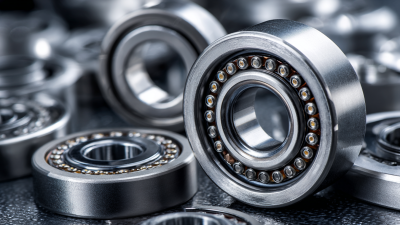

25mm pillow block bearings play a critical role in various industrial applications due to their ability to support rotating shafts and reduce friction. These bearings are engineered to withstand harsh conditions, making them vital in sectors like mining, warehousing, and manufacturing. According to a recent report, the demand for mounted bearings is projected to grow significantly, driven by the evolving needs of industries that require reliable performance under heavy loads and extreme environments.

In particular, the introduction of heavy-duty mounted units designed to handle the rigors of mining applications highlights the importance of robust bearing solutions. These advancements in bearing technology aim to reduce downtime, which is a critical factor in optimizing operational efficiency. Coupled with the deployment of innovative designs, the industry is seeing enhanced performance and longevity in applications that require frequent maintenance, underscoring how essential pillow block bearings are in keeping machinery running smoothly.

Furthermore, with the ongoing developments in the field, manufacturers are increasingly focusing on creating products that offer adaptability and strength, aligning with the needs of modern industrial processes. The shift towards more durable and efficient bearing solutions is crucial for maintaining competitive edge and ensuring the reliability of equipment across various applications.

What You Need to Know About 25mm Pillow Block Bearing

| Application | Load Capacity (kg) | Speed Rating (RPM) | Material | Temperature Range (°C) |

|---|---|---|---|---|

| Conveyor Systems | 200 | 1800 | Cast Iron | -20 to 80 |

| Agricultural Equipment | 250 | 1600 | Steel | -10 to 90 |

| Automotive Industry | 180 | 2000 | Bronze | -20 to 85 |

| Manufacturing Machinery | 300 | 1500 | Nylon | -10 to 70 |

| HVAC Units | 150 | 1200 | Aluminum | -20 to 60 |

Key Specifications and Standards for 25mm Pillow Block Bearings: A Comprehensive Overview

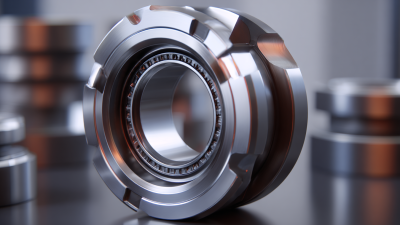

When considering 25mm pillow block bearings, it is crucial to understand the key specifications and standards that define their performance and application. These bearings typically feature a bore diameter of 25mm, allowing for compatibility with various shafts. The outer diameter and base dimensions vary based on the manufacturer, affecting mounting methods and load distribution.

Pillow block bearings are designed to accommodate radial loads and can handle moderate axial loads, making them ideal for use in conveyor systems, automotive applications, and industrial machinery.

Pillow block bearings are designed to accommodate radial loads and can handle moderate axial loads, making them ideal for use in conveyor systems, automotive applications, and industrial machinery.

Another vital aspect is the materials and seal types used in the construction of these bearings. Most pillow block bearings are made from high-quality steel or plastic, ensuring durability and resistance to wear. The inclusion of seals or shields can enhance their protection against contaminants, prolonging the bearing life and improving reliability in harsh environments.

Standards such as ISO 9001 help ensure quality and consistency in manufacturing, giving users confidence in their selection and installation of 25mm pillow block bearings for various industrial applications.

Market Trends: Growth and Demand for 25mm Pillow Block Bearings in Industrial Sectors

The demand for 25mm pillow block bearings is experiencing robust growth within various industrial sectors, driven by technological advancements and increasing automation. Industries such as manufacturing, automotive, and construction are actively incorporating these bearings due to their reliability and efficiency in supporting rotating shafts. As machinery becomes more sophisticated, the need for durable components like pillow block bearings has escalated, highlighting their essential role in improving operational performance and reducing downtime.

Recent innovations in materials, including phase change materials (PCM), are further influencing the market trends for pillow block bearings. These advancements allow for better thermal management and enhanced lifecycle, making them appealing for industries that require durable yet efficient components. Additionally, as sectors evolve towards more patient-centric and value-based models, the role of reliable mechanical components remains crucial. The forecast for the pillow block bearings market indicates sustained growth as industries increasingly rely on high-performing solutions to meet their complex demands.

Market Trends: Growth and Demand for 25mm Pillow Block Bearings

This chart illustrates the increasing demand for 25mm pillow block bearings in industrial sectors from 2019 to 2023. As industries continue to grow and evolve, the need for reliable bearing solutions has significantly influenced market trends.

Comparative Analysis: 25mm Pillow Block Bearings vs. Other Bearing Types and Sizes

When comparing 25mm pillow block bearings to other bearing types and sizes, several factors come into play, including load capacity, versatility, and installation ease. According to a report by the International Journal of Engineering, pillow block bearings are favored for their ability to accommodate misalignment, which can enhance their lifespan by approximately 20% compared to standard bearings. This makes them particularly suited for applications in manufacturing and agricultural equipment, where alignment issues often arise.

Additionally, the size of the bearing plays a critical role in its application. A study published by the Bearing Manufacturer Association reveals that while 25mm bearings are optimal for medium-load applications, larger sizes such as 35mm or 50mm are better suited for high-load scenarios. This is vital for engineers to consider when designing machinery, as using the correct bearing size can significantly reduce downtime and maintenance costs. Furthermore, the report highlights that the global market for pillow block bearings is expected to grow at a rate of 5.2% annually, underscoring their increasing importance in various industries.

Maintenance Best Practices for Enhancing the Lifespan of 25mm Pillow Block Bearings

Maintaining 25mm pillow block bearings is crucial for maximizing their lifespan and ensuring optimal performance in various applications. According to a report by the American Society of Mechanical Engineers, proper maintenance can enhance bearing longevity by up to 50%. Regular inspections should focus on checking for signs of wear, ensuring that the mounting surfaces are clean, and verifying that the bearings are properly lubricated. Lubrication plays a pivotal role; experts recommend using a high-quality grease that meets the manufacturer's specifications and reapplying it based on the operating conditions, typically every 6 to 12 months.

Additionally, it's important to monitor the operating temperature of pillow block bearings. A study published in the Journal of Tribology indicates that excessive heat can lead to premature failure, potentially shortening the bearing's lifespan by more than 30%. Installing temperature sensors can provide real-time data, allowing for early interventions if temperatures spike. By adopting these best maintenance practices—regular lubrication, temperature monitoring, and thorough inspections—manufacturers can significantly improve the reliability and life expectancy of their 25mm pillow block bearings.

Related Posts

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

How to Choose the Right Cast Steel Block Bearing for Your Industrial Needs

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

How to Choose the Right Stainless Steel Bearing for Your Application