How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

In the complex world of machinery, selecting the right roller bearing is critical for ensuring optimal performance and longevity. Roller bearings are essential components that reduce friction and wear in rotating systems, significantly impacting operational efficiency. According to a report by the National Lubricating Grease Institute, the correct choice of roller bearings can improve machinery lifespan by up to 30%, while inadequate selections may lead to premature failure and costly downtime. Furthermore, the global roller bearing market is projected to reach approximately $42 billion by 2025, reflecting the industry's recognition of the vital role these components play in machinery. Therefore, understanding the different types of roller bearings and their specific applications is crucial for engineers and maintenance professionals who aim to enhance reliability and drive down operational costs. This article delves into the key factors to consider when choosing roller bearings, ensuring that your machinery operates at peak efficiency and durability.

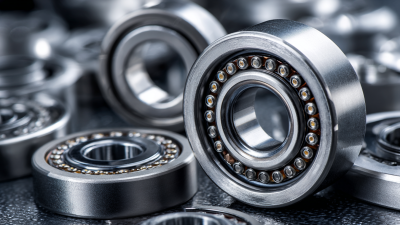

Understanding Different Types of Roller Bearings for Your Machinery Needs

When it comes to machinery performance, selecting the appropriate type of roller bearing is crucial for ensuring durability and efficiency. There are several types of roller bearings, including cylindrical, spherical, and tapered roller bearings, each designed to handle specific loads and conditions. According to a report by the International Journal of Engineering Research & Technology, the choice of roller bearings can impact energy efficiency by as much as 10% to 30%, significantly influencing operational costs over time.

Cylindrical roller bearings are ideal for applications requiring high radial loads, while tapered roller bearings are well-suited for applications that experience both radial and axial loads. Spherical roller bearings, on the other hand, provide greater versatility in alignment and are perfect for heavy-duty machinery. A study from the American Bearing Manufacturers Association highlights that using roller bearings optimized for specific machines can reduce maintenance costs by about 20% and extend equipment life by 30%, thereby offering a compelling cost-saving advantage for manufacturers and operators alike. Understanding these distinctions is essential for making informed decisions that enhance machinery performance and longevity.

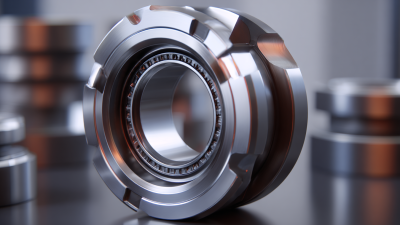

Key Factors to Consider When Selecting Roller Bearings

When selecting roller bearings, several key factors must be considered to ensure optimal performance and longevity in machinery applications. Load capacity is critical; for instance, tapered roller bearings are increasingly utilized in demanding environments such as wind turbine gearboxes due to their ability to withstand high loads. According to recent studies, proper understanding of bearing load ratings can enhance reliability, especially in applications like offshore wind energy systems.

Another essential aspect is the tribological performance of the bearings, influenced by parameters such as material composition and surface treatments. Research indicates that enhancing tribological properties, through methods like niobium and nitrogen implantation, significantly improves performance under conditions of limited lubrication. Furthermore, the rotational accuracy of cylindrical roller bearings can be affected by roundness errors of bearing components, highlighting the importance of precision in manufacturing processes. Optimizing these variables not only ensures smoother operation but also extends the service life of the bearings, which is critical in reducing maintenance costs and improving operational efficiency in machinery.

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery - Key Factors to Consider When Selecting Roller Bearings

| Parameter | Description | Importance Level | Recommended Value/Range |

|---|---|---|---|

| Load Capacity | Maximum load the bearing can handle without failure. | High | Varies by application, typically > 10,000 N |

| Speed Rating | Maximum rotational speed before risk of failure. | High | 1500 - 10,000 RPM |

| Material | Material of the bearing's rolling elements and races. | Medium | Chrome steel, stainless steel, ceramic |

| Lubrication Type | Type of lubricant used in the bearing. | High | Grease, oil |

| Bearing Fit | Precision of bearing installation in relation to the housing and shaft. | Medium | Interference fit or clearance fit as required |

| Environmental Resistance | Ability to withstand harsh environments (moisture, dust, temperature). | High | Sealed or shielded bearings recommended |

| Vibration Control | Ability to operate smoothly with minimal vibrations. | Medium | Balanced design and proper installation required |

Tips for Maximizing Bearing Lifespan and Reducing Downtime

When it comes to maximizing the lifespan of roller bearings and reducing downtime in machinery, several key factors should be considered. Regular lubrication is critical; according to a report by the American Society of Mechanical Engineers (ASME), nearly 40% of bearing failures can be attributed to inadequate lubrication. Selecting the right type of lubricant—whether it be grease or oil—tailored to the specific operating conditions is essential for maintaining optimal performance. Ensuring an appropriate lubrication schedule can significantly enhance bearing durability, potentially extending service life by up to 50%.

In addition to proper lubrication, it’s vital to ensure accurate alignment during installation. Misalignment can lead to increased load, excessive wear, and eventual premature failure. Industry statistics indicate that misalignment accounts for approximately 30% of mechanical failures in rotating equipment. Conducting regular inspections and employing precision alignment techniques can mitigate these risks. Furthermore, maintaining clean operating conditions and monitoring operating temperatures can also play a significant role in bearing longevity, with excessive heat being a known adversary, often leading to reduced bearing life by as much as 20%. By meticulously following these best practices, you can help ensure the longevity and reliability of your machinery's roller bearings.

Optimizing Roller Bearing Performance: Lifespan and Downtime Analysis

This chart illustrates the key factors affecting the lifespan of roller bearings in machinery. As shown, maintaining an effective lubrication regimen and ensuring high-quality installation significantly extend the operational lifespan of bearings, thereby minimizing downtime and improving overall machinery performance.

Evaluating Load Ratings and Speed Limits for Optimal Performance

When selecting roller bearings for your machinery, understanding load ratings and speed limits is crucial for ensuring optimal performance and longevity. Load ratings indicate the maximum load a bearing can support while maintaining its performance under specified conditions. It’s essential to match these ratings to the operational requirements of your machinery. Overloading a bearing can lead to premature wear or failure, so always calculate the expected loads carefully.

Speed limits are equally important; each roller bearing is designed to operate efficiently within a specific speed range. Operating beyond these limits can generate excessive heat and vibrations, causing damage. Consulting manufacturer's specifications will provide insights into the appropriate speed capabilities for your selected bearing.

**Tips:** Always consider both dynamic and static load ratings when evaluating bearings for your application. Additionally, remember that environmental factors, such as temperature and lubrication, can impact load ratings and speed limits, so take these into account during your selection process. Lastly, when in doubt, seek guidance from bearing specialists to ensure you are choosing the right components for optimal machinery performance.

Maintenance Practices to Ensure Long-lasting Roller Bearings in Equipment

To ensure the longevity of roller bearings in machinery, regular maintenance practices are crucial. One fundamental aspect is the routine inspection of bearings for signs of wear, such as discoloration, pitting, or abnormal noises. Establishing a consistent inspection schedule helps in identifying potential issues before they escalate, thus preventing costly downtime. It's also advisable to keep a detailed maintenance log to track the performance and service history of the bearings.

Additionally, proper lubrication is essential in maintaining roller bearings. Selecting the right lubricant plays a significant role in reducing friction and preventing overheating. Every bearing type has specific lubrication guidelines that should be adhered to, including the frequency of lubrication and the type suited for the operating conditions. Cleanliness during lubrication and maintenance procedures is also vital to avoid contamination that can lead to premature bearing failure. Implementing these practices will help maintain optimal performance and extend the lifespan of roller bearings in any equipment.