How to Choose the Right Stainless Steel Bearing for Your Application

Choosing the right stainless steel bearing for your application is crucial to ensuring optimal performance and longevity of your machinery. Stainless steel bearings offer unique advantages due to their resistance to corrosion and high durability, making them an ideal choice for environments that are exposed to moisture and harsh conditions. However, with various types of stainless steel bearings available on the market, selecting the most suitable one can be a daunting task. This guide will explore key factors to consider when choosing a stainless steel bearing, including load requirements, operating conditions, and maintenance needs. By understanding these critical aspects, you can make an informed decision that aligns with the specific demands of your application, ultimately enhancing efficiency and reducing downtime.

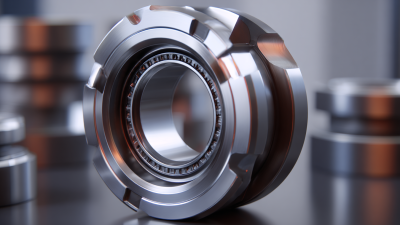

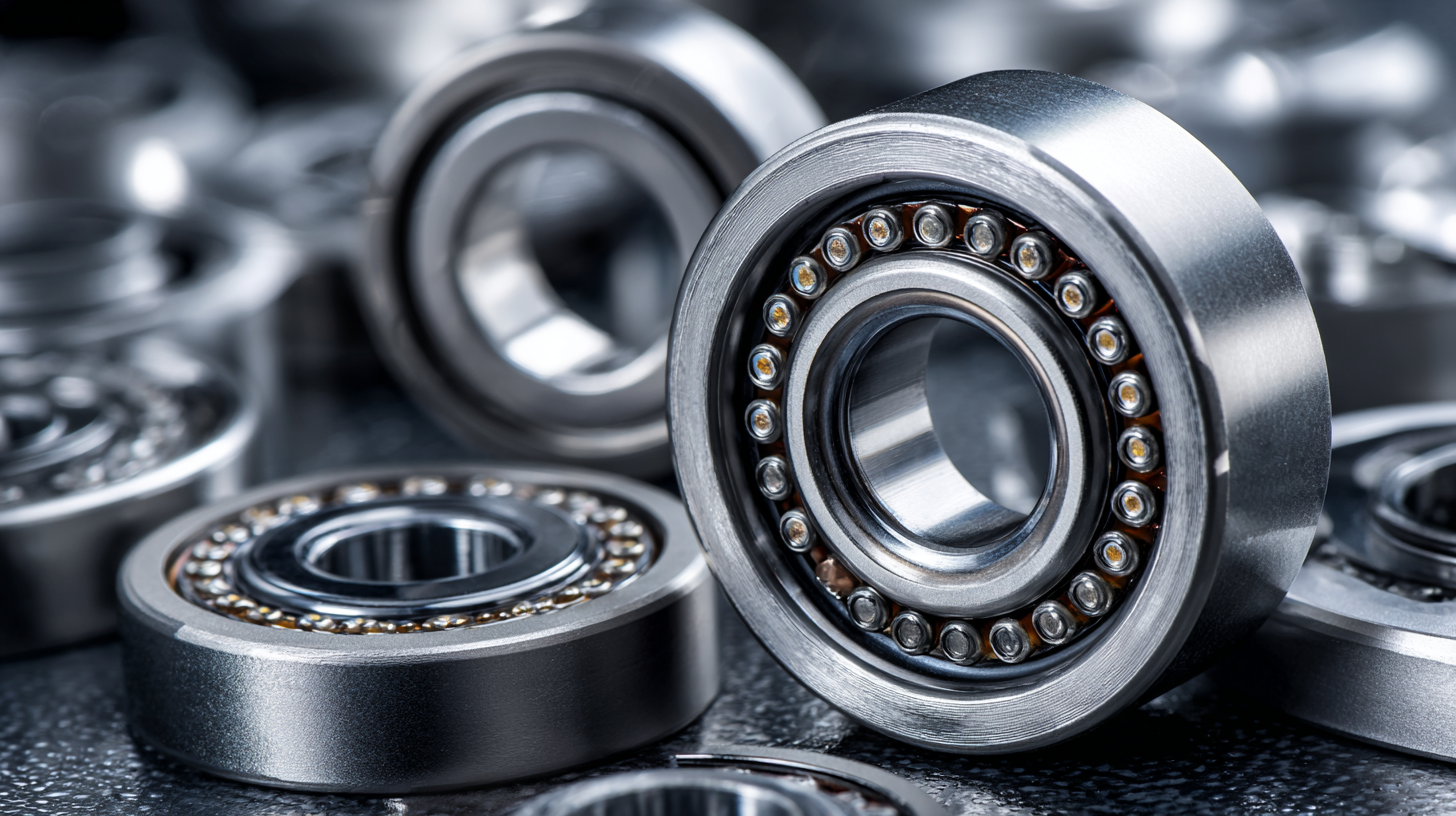

Understanding Different Types of Stainless Steel Bearings and Their Applications

When selecting the right stainless steel bearing for your application, it is crucial to understand the various types available and their specific uses. The global bearing steel market is projected to reach USD 2.57 billion by 2030, growing at a compound annual growth rate (CAGR) of 2.7% from 2022 to 2030. This growth reflects the increasing demand for high-performance components in multiple industries, including automotive and aerospace. Stainless steel bearings are particularly valued for their exceptional resistance to corrosion and wear, making them ideal for applications exposed to harsh environments.

Different types of stainless steel bearings can cater to various operational needs. For instance, radial insert ball bearings are designed specifically for food and beverage applications due to their hygienic properties and robustness. Additionally, advancements in materials science, such as polymer coatings, enhance the performance of bearings, further expanding their application spectrum.

Understanding the characteristics and benefits of each type is essential for optimizing performance and longevity in your specific application. Always consider the operational conditions and material compatibility when making your choice to ensure maximum efficiency and safety.

Key Factors to Consider When Selecting Stainless Steel Bearings

When selecting the right stainless steel bearing for your application, several key factors must be considered to ensure optimal performance and longevity. One critical aspect is the bearing's corrosion resistance, particularly in environments exposed to moisture or chemicals. According to a report by the Bearing Industry Manufacturers Association (BIMA), stainless steel bearings have a corrosion resistance rating up to 10 times higher than standard carbon steel bearings, making them ideal for marine, pharmaceutical, and food processing applications where hygiene and durability are paramount.

Another important factor is the load and speed requirements of your application. Stainless steel bearings are available in various grades, with AISI 440C often recommended for high-load applications due to its hardness and wear resistance. A study by the International Organization for Standardization (ISO) indicates that bearings made from high-quality stainless steel exhibit fatigue life improvements of up to 50% compared to standard materials under similar stress conditions. Therefore, assessing the operational parameters, including load, speed, and environmental exposure, will guide you in choosing the right stainless steel bearing for your specific needs.

Evaluating Load Capacities and Speed Ratings for Optimal Performance

When selecting the appropriate stainless steel bearing for your application, evaluating load capacities and speed ratings is crucial for ensuring optimal performance. Load capacity defines the maximum weight that a bearing can support without failure, typically articulated through dynamic and static load ratings. Understanding these capacities requires analyzing the operating conditions, including the type of load (radial, axial, or combined) and the environment in which the bearing will operate. Choosing a bearing with a load capacity that exceeds the anticipated loads will enhance durability and reliability.

In addition to load capacities, speed ratings play a significant role in performance evaluation. Each bearing design has a specific maximum speed, determined by factors such as material properties, lubrication, and heat generation. Exceeding the recommended speed can lead to premature wear or catastrophic failure. It's essential to consider not only the rotational speed but also the acceleration rates and any potential intermittent loads. By carefully assessing both load capacities and speed ratings, you can ensure that your stainless steel bearing will function effectively within the parameters of your application.

Comparing Corrosion Resistance and Environmental Conditions

When choosing the right stainless steel bearing for your application, one of the most critical factors to consider is corrosion resistance, especially in varied environmental conditions. Recent studies highlight the significant role environmental factors play in corrosion rates for materials used in different applications. For example, a comprehensive review on the atmospheric corrosion of carbon and galvanized steel indicates that high rainfall can notably increase corrosion rates, emphasizing the importance of selecting materials suited for moisture-prone environments.

Moreover, advancements in alloy compositions and surface treatments have proven effective in enhancing the corrosion resistance of materials. Research on nickel-based alloys shows that their exceptional properties, including oxidation and corrosion resistance, can be significantly improved by tailored alloying elements. This is crucial for applications exposed to harsh conditions, such as those found in marine environments. Therefore, when selecting stainless steel bearings, it is essential to evaluate the specific environmental conditions they will face and choose alloys and treatments that meet the expected performance requirements, aligning with recent industry findings on corrosion prevention methods.

Maintenance Tips for Prolonging the Life of Stainless Steel Bearings

To prolong the life of stainless steel bearings, regular maintenance is essential. One of the most critical practices is to ensure that the bearings are kept clean and free from contaminants. Dust, dirt, and grime can affect the performance and lifespan of bearings significantly. Using a soft brush or cloth to wipe down the outer surfaces, along with periodic deep cleaning using ultrasonic baths, can help maintain optimal performance.

Lubrication is another key aspect of bearing maintenance. It is crucial to select the right lubricant based on the operating conditions, such as temperature and load. Over-lubrication can lead to excessive heat and joint failure, while under-lubrication may cause premature wear. Therefore, it is important to adhere to manufacturer recommendations regarding lubrication intervals and quantities. Regularly checking and adjusting the lubricant can prevent damage and enhance the bearing's durability. Additionally, monitoring for any unusual noises or vibrations can signal potential issues, allowing for timely interventions before severe damage occurs.

How to Choose the Right Stainless Steel Bearing for Your Application - Maintenance Tips for Prolonging the Life of Stainless Steel Bearings

| Bearing Type | Load Capacity (N) | Speed Rating (RPM) | Material | Maintenance Frequency (months) |

|---|---|---|---|---|

| Deep Groove Ball Bearing | 8000 | 5000 | AISI 440C | 6 |

| Angular Contact Ball Bearing | 9500 | 4000 | AISI 316 | 4 |

| Thrust Ball Bearing | 6000 | 3200 | AISI 304 | 12 |

| Self-Aligning Ball Bearing | 7200 | 3500 | AISI 440A | 8 |

| Roller Bearing | 10000 | 3000 | AISI 420 | 10 |