How to Choose the Right Cast Steel Block Bearing for Your Industrial Needs

In today's industrial landscape, selecting the appropriate Cast Steel Block Bearing is crucial for ensuring optimal performance and reliability in machinery. According to a recent industry report by Research and Markets, the global bearing market is projected to reach USD 100 billion by 2025, with a significant growth driven by advancements in manufacturing technology and rising demand from sectors such as automotive, aerospace, and heavy machinery. Cast Steel Block Bearings are favored for their strength and durability, capable of withstanding heavy loads and extreme conditions. As industries strive for efficiency and longevity in their equipment, understanding the specific requirements of each application becomes vital. This guide aims to provide insights into the critical factors involved in choosing the right Cast Steel Block Bearing to meet your industrial needs, ensuring enhanced performance and reduced downtime.

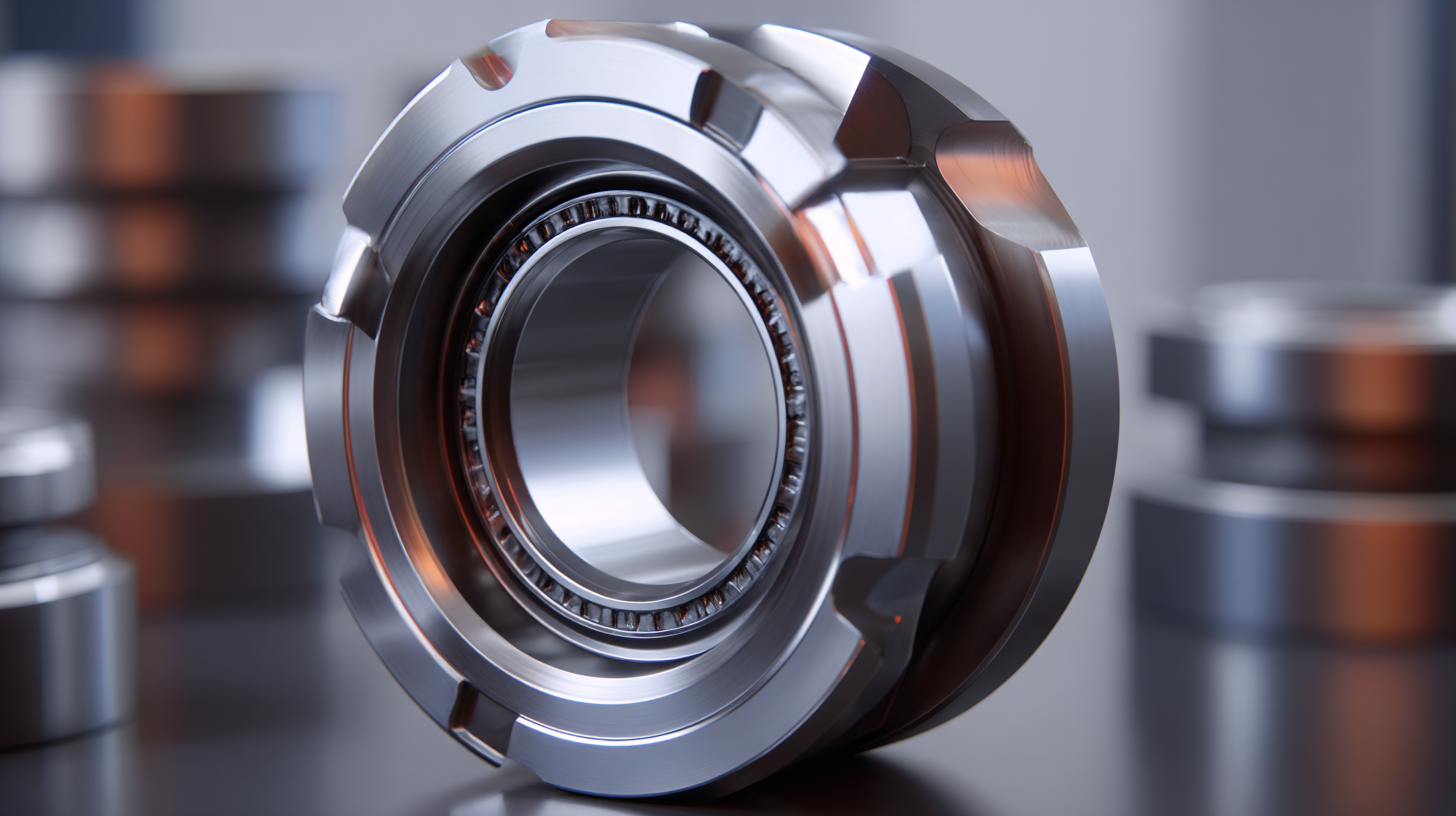

Understanding the Different Types of Cast Steel Block Bearings

When selecting the right cast steel block bearing for industrial applications, it is crucial to understand the various types available and their specific attributes. According to a recent industry report by Research and Markets, the global market for bearings is projected to reach $150 billion by 2027, reflecting a growing demand for efficient and durable solutions. Cast steel block bearings are lauded for their superior load-carrying capacity and resilience, making them ideal for heavy machinery and equipment in sectors such as manufacturing, mining, and construction.

There are several types of cast steel block bearings to consider, each designed for specific conditions. For instance, pillow block bearings, often utilized in conveyor systems, provide support for rotating shafts and enhance stability. Another variant, flanged block bearings, are designed for ease of installation and alignment, which is critical in high-speed applications.

A market analysis from Mordor Intelligence indicates that industries are increasingly opting for high-performance bearings due to the rise of automation and the need for increased operational efficiency. This highlights the importance of choosing the right type of bearing to match specific operational requirements, ensuring reliability and longevity in performance.

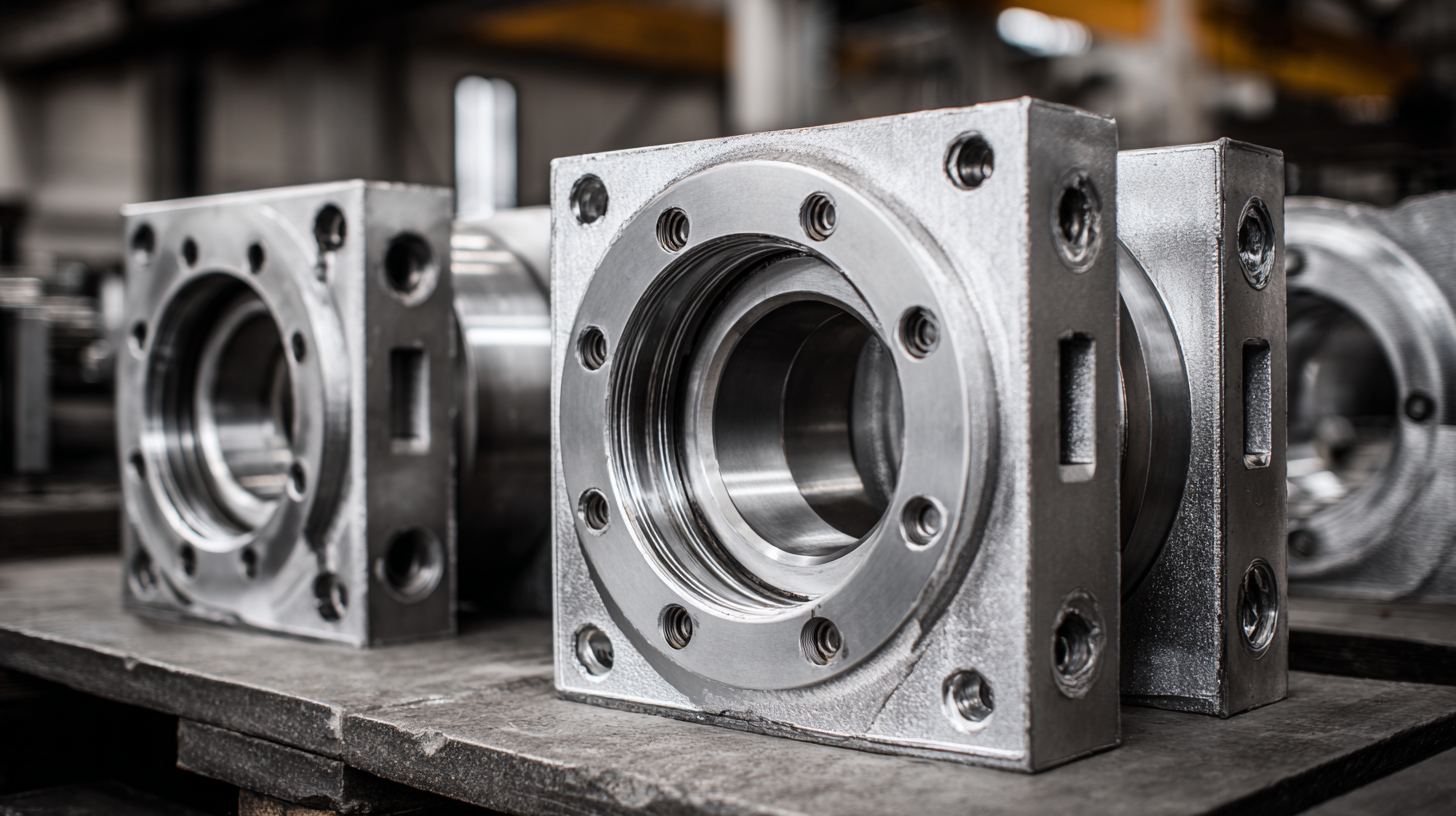

Key Factors to Consider When Selecting Cast Steel Block Bearings

When selecting cast steel block bearings for industrial applications, several key factors must be considered to ensure optimal performance and longevity. One of the most crucial aspects is load capacity, which directly affects the bearing's ability to handle different operational stresses. According to the International Journal of Engineering Research, the proper selection of bearings based on load ratings can improve equipment efficiency by more than 20%. Additionally, examining the environmental conditions in which the bearing will operate—such as humidity, temperature fluctuations, and exposure to chemicals—can prevent premature wear and tear.

Tips for choosing the right cast steel block bearings include ensuring compatibility with shaft dimensions and verifying the type of lubrication that will be used. Using the wrong size can lead to excessive play and vibrations, posing risks to machinery operation. Furthermore, analyzing frequency and duration of use can guide your choice of bearing design; for heavy-duty applications, a bearing with a higher grease capacity is advisable, as reported by the American Institute of Aeronautics and Astronautics.

Another essential consideration is the available support and maintenance services. Opting for a manufacturer that offers comprehensive support and accessibility to replacement parts can significantly reduce downtime and maintenance costs in the long run. Regular maintenance practices can extend the life of cast steel block bearings and enhance overall machine reliability.

Assessing Load Capacity and Operating Conditions for Optimal Performance

When selecting the right cast steel block bearing for industrial applications, understanding the load capacity and operating conditions is crucial for optimal performance. According to the American Society of Mechanical Engineers (ASME), load capacity is often defined in terms of radial and axial loads, which can significantly influence the lifespan and efficiency of the bearing. For instance, a bearing rated for a dynamic load of 12,000 Newtons is typically designed to support rotational applications in environments with high-speed operations, ensuring it can handle expected stresses without premature failure.

Operating conditions also play a vital role in bearing selection. Factors such as temperature, humidity, and contamination levels can affect performance and longevity. A report from the International Organization for Standardization (ISO) indicates that bearings used in temperature ranges exceeding 100 degrees Celsius may require special materials or lubricants to prevent degradation. Additionally, considering the presence of dirt or moisture can help in choosing seals or shields that enhance protection against external contaminants, thereby extending service life. Ensuring that both load capacity and operating conditions are aligned with the specific requirements of the application can lead to enhanced reliability and reduced maintenance costs in industrial operations.

Maintenance and Longevity: Choosing Bearings That Suit Your Needs

When it comes to selecting cast steel block bearings,

maintenance and longevity are key factors that cannot be overlooked. Proper maintenance strategies

are essential not only for the performance of the bearings but also for extending their operational life.

Regular inspections, adequate lubrication, and timely replacements of worn components are critical practices

that ensure bearings remain in optimal condition.

Additionally, understanding the specific environmental conditions and operational demands will help in

choosing bearings that can withstand the rigors of industrial use.

Additionally, understanding the specific environmental conditions and operational demands will help in

choosing bearings that can withstand the rigors of industrial use.

Choosing the right cast steel block bearing also involves considering factors such as load capacity and wear resistance. Selecting bearings designed with durable materials can significantly enhance their longevity, especially in high-stress applications. Engaging with manufacturers who provide detailed specifications and maintenance guidelines can further assist in making informed decisions. Ultimately, investing in the right bearings with an emphasis on maintenance will lead to improved efficiency and reduced downtime in industrial operations, paving the way for sustained productivity.

Cost Analysis: Evaluating Value versus Price in Cast Steel Block Bearings

When evaluating the cost of cast steel block bearings for industrial applications, it's crucial to consider the balance between value and price. According to a report by Research and Markets, the global cast steel bearings market is projected to grow significantly, driven by the rising demand for durable and reliable machinery components. The initial cost can often be misleading; investing in higher-quality bearings can lead to long-term savings through reduced maintenance and downtime. The average lifecycle cost of a bearing can exceed five times its purchase price when factoring in potential failures and production losses.

Additionally, a study by the American Bearing Manufacturers Association highlights that premium cast steel block bearings can offer enhanced performance characteristics, such as increased load-bearing capacity and resistance to wear and corrosion. These features not only improve operational efficiency but also extend the lifespan of machinery, which ultimately translates into lower operational costs. For industries that rely heavily on robust machinery, understanding the total cost of ownership (TCO) rather than just the upfront expenditure is essential for making informed purchasing decisions.