Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

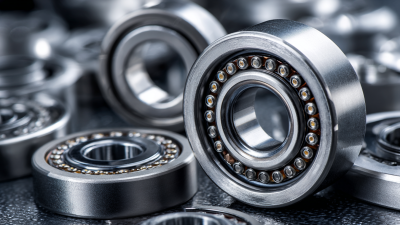

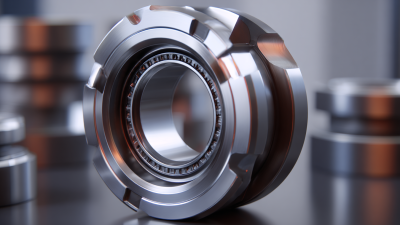

The bearing manufacturing industry is undergoing a significant transformation driven by advancements in technology and innovative factory processes. As reported by the Global Bearings Market Research, the industry is expected to reach a value of $100 billion by 2025, highlighting the critical role of efficiency in Bearing Factory operations. Manufacturers are increasingly adopting digital solutions, such as IoT and automation, to enhance productivity and precision. A study conducted by Deloitte indicated that companies implementing digital manufacturing processes could realize an increase in efficiency by up to 30%. This evolution not only aims to reduce production costs but also to improve the quality and reliability of bearings, vital components used across various sectors including automotive, aerospace, and renewable energy. By exploring the innovative strides made in Bearing Factory processes, we can better understand how these developments are shaping the future of the bearings industry.

The bearing manufacturing industry is undergoing a significant transformation driven by advancements in technology and innovative factory processes. As reported by the Global Bearings Market Research, the industry is expected to reach a value of $100 billion by 2025, highlighting the critical role of efficiency in Bearing Factory operations. Manufacturers are increasingly adopting digital solutions, such as IoT and automation, to enhance productivity and precision. A study conducted by Deloitte indicated that companies implementing digital manufacturing processes could realize an increase in efficiency by up to 30%. This evolution not only aims to reduce production costs but also to improve the quality and reliability of bearings, vital components used across various sectors including automotive, aerospace, and renewable energy. By exploring the innovative strides made in Bearing Factory processes, we can better understand how these developments are shaping the future of the bearings industry.

Advancements in Bearing Manufacturing: The Role of Digital Technologies

Digital technologies are revolutionizing the bearing manufacturing industry, enhancing efficiency and precision across various production processes. According to the International Bearing Association, the adoption of advanced automation technologies has improved manufacturing productivity by up to 30%. This shift towards automation not only minimizes human error but also accelerates production cycles, allowing manufacturers to meet increasing global demands without compromising on quality.

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) into bearing production is also noteworthy. For instance, predictive maintenance powered by AI algorithms can significantly reduce unexpected machinery downtime, which has been reported to save manufacturers around 20% in maintenance costs annually. Moreover, real-time data analytics enables manufacturers to monitor production processes and quality in real-time, leading to enhanced decision-making and reduced waste. The impact of these digital advancements is evident, as manufacturers that adopt such technologies are better positioned to compete in an increasingly challenging market landscape.

Exploring the Science Behind Bearing Manufacturing: Innovations in Bearing Factory Processes

| Process Stage | Technology Used | Benefits | Impact on Manufacturing |

|---|---|---|---|

| Material Selection | AI-driven analysis | Improved efficiency in selecting optimal materials | Higher product performance and durability |

| Manufacturing Process | Additive Manufacturing (3D Printing) | Reduced waste and customization opportunities | Flexibility in design and rapid prototyping |

| Quality Control | IoT Sensors | Real-time monitoring of quality metrics | Minimized defects and enhanced product reliability |

| Assembly | Robotic Automation | Faster assembly times and improved precision | Increased production capacity and lower labor costs |

| Testing | Virtual Simulation | Cost-effective testing without physical prototypes | Faster innovation cycles and reduced time to market |

Integrating Automation in Bearing Production: Enhancing Efficiency and Precision

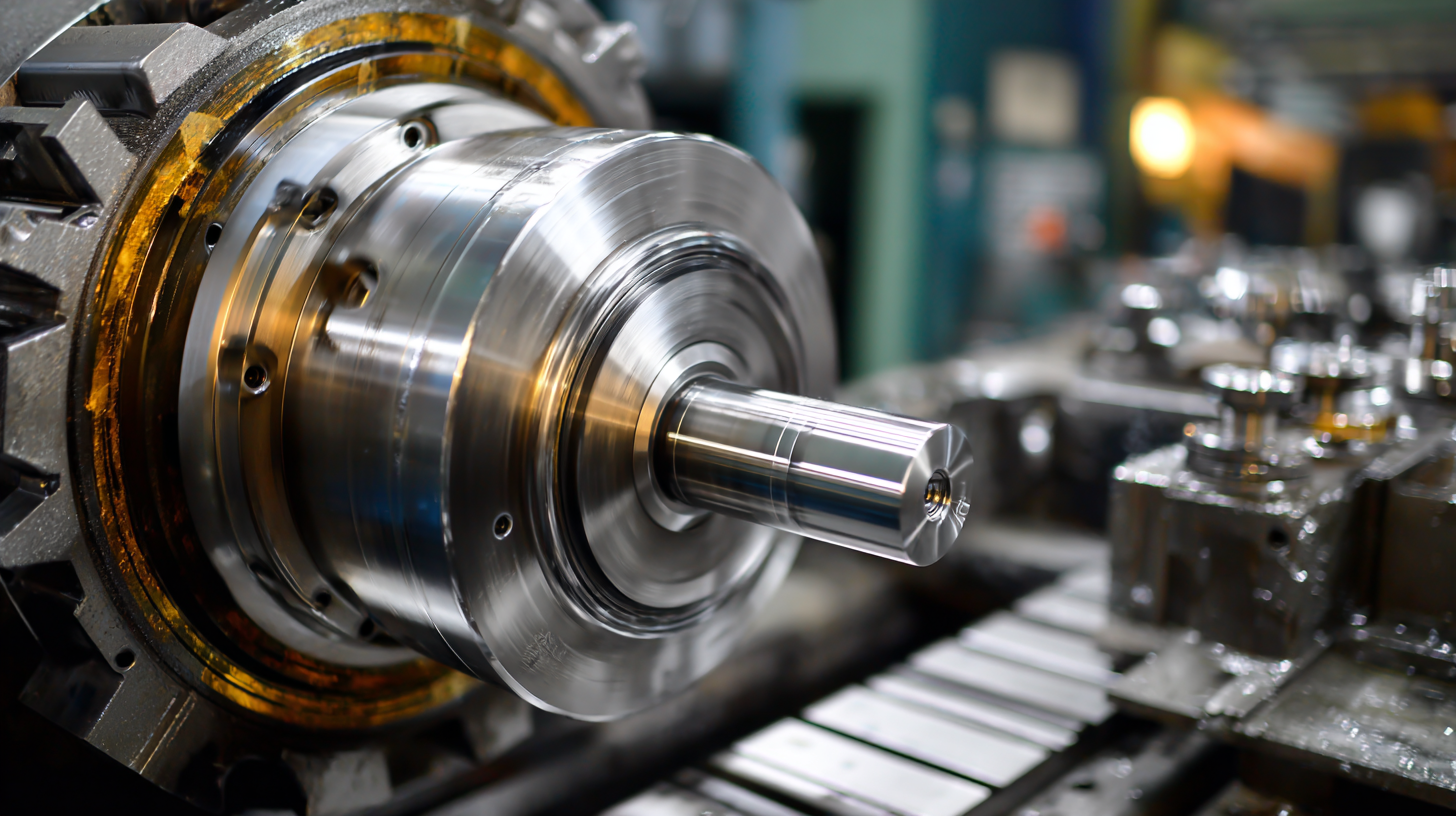

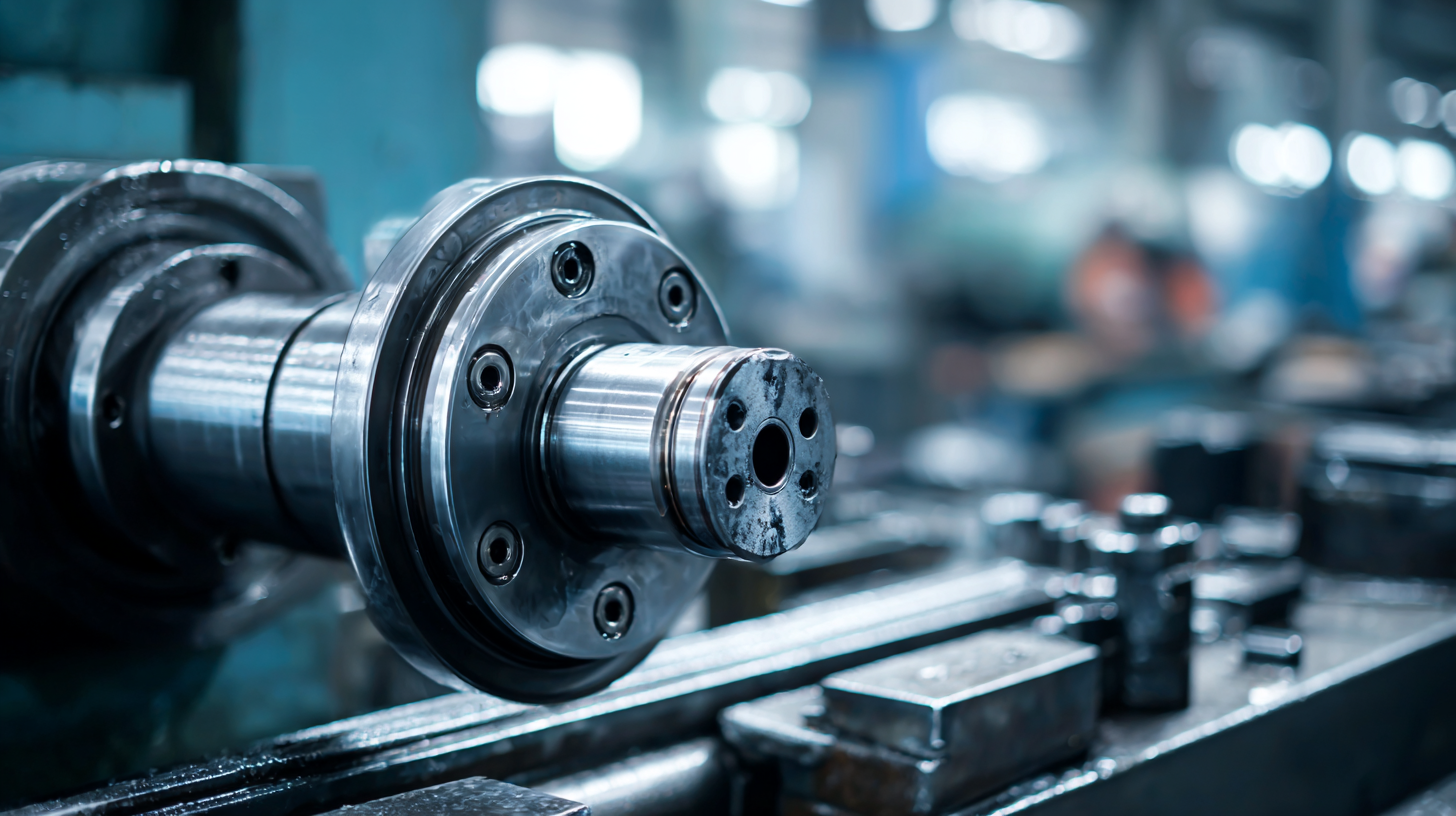

The integration of automation in bearing production has revolutionized the manufacturing landscape, significantly enhancing efficiency and precision. According to a recent industry report by MarketsandMarkets, the global bearing market is projected to grow from USD 99.41 billion in 2021 to USD 117.58 billion by 2026, driven in part by advancements in automated production technologies. Automated systems streamline processes such as assembly, quality control, and packaging, allowing manufacturers to reduce cycle times and minimize human error. For instance, automated machining centers can perform multiple operations simultaneously, leading to a 30% increase in production speed.

The integration of automation in bearing production has revolutionized the manufacturing landscape, significantly enhancing efficiency and precision. According to a recent industry report by MarketsandMarkets, the global bearing market is projected to grow from USD 99.41 billion in 2021 to USD 117.58 billion by 2026, driven in part by advancements in automated production technologies. Automated systems streamline processes such as assembly, quality control, and packaging, allowing manufacturers to reduce cycle times and minimize human error. For instance, automated machining centers can perform multiple operations simultaneously, leading to a 30% increase in production speed.

Tips: Embrace Industry 4.0 technologies, like IoT-enabled machines, to gather real-time data for better decision-making. This can enhance predictive maintenance strategies and reduce downtime, ultimately maximizing productivity.

Moreover, the precision offered by automated systems is crucial in industries where high-performance bearings are essential, such as aerospace and automotive. Automation not only ensures consistent quality but also allows for the mass customization of bearing solutions tailored to specific applications. According to a study published by Grand View Research, the increasing demand for customized bearings in these sectors is expected to push manufacturers toward adopting more advanced automation solutions.

Tips: Invest in training your workforce to adapt to new technologies, ensuring that they are equipped to handle and maintain advanced automated equipment effectively. This investment can yield long-term benefits by fostering a culture of continuous improvement and innovation.

Quality Control Innovations: Ensuring Consistency in Bearing Manufacturing

Quality control is a critical aspect of bearing manufacturing, ensuring that each product meets stringent performance and reliability standards. Innovations in quality control processes are revolutionizing how factories monitor and maintain consistency. Advanced technologies, such as automated inspection systems powered by artificial intelligence, enable real-time quality assessments at various stages of production. These systems can detect defects or deviations from specifications with remarkable precision, reducing the reliance on manual inspections and improving overall efficiency.

Additionally, the integration of data analytics in quality control practices allows manufacturers to track performance metrics over time. By analyzing historical data and trends, factories can proactively identify potential issues before they escalate into significant problems. This predictive approach not only minimizes scrap and rework but also enhances the lifespan and performance reliability of the bearings produced. As a result, manufacturing facilities equipped with these innovative quality control measures are better positioned to meet increasing market demands while upholding high standards of excellence.

Sustainable Practices in Bearing Factories: Balancing Production and Environment

Sustainable practices in bearing factories are becoming increasingly crucial as the industry seeks to balance production demands with environmental stewardship. According to a report by Market Research Future, the global bearing market is projected to grow at a CAGR of 5.2% between 2020 and 2027, driven by the rising demand for efficient machinery across sectors. This growth necessitates a shift towards sustainable manufacturing processes, where factories adopt eco-friendly materials and energy-efficient technologies.

One innovative approach involves the use of recycled materials in bearing production. A study by the International Journal of Precision Engineering and Manufacturing found that incorporating recycled steels can reduce carbon emissions by up to 60% compared to traditional methods. Additionally, many manufacturers are investing in renewable energy sources. For instance, a recent survey by the International Energy Agency indicated that nearly 30% of European bearing manufacturers have committed to utilizing solar or wind energy in their operations by 2025, which not only lowers their carbon footprint but also enhances their operational efficiency. These advancements illustrate the industry's dedication to harmonizing production needs with environmental responsibility.

Innovations in Bearing Manufacturing Processes

Future Trends in Bearing Manufacturing: Embracing Smart Factory Concepts

The future of bearing manufacturing is increasingly intertwined with the concept of smart factories, where advanced technologies such as IoT, AI, and automation drive efficiency and precision. According to a recent report from MarketsandMarkets, the global smart factory market is projected to reach $500 billion by 2025, reflecting a compound annual growth rate (CAGR) of 10.4% from 2020. This trend emphasizes the need for bearing manufacturers to adopt smart technologies to enhance production capabilities and meet rising demands for high-performance components.

Innovations such as predictive maintenance and real-time data analytics are transforming traditional bearing manufacturing processes. A study by McKinsey highlights that manufacturers who implement IoT solutions can achieve efficiency improvements of 20-30%. By leveraging these technologies, bearing manufacturers not only reduce downtime but also optimize resource usage, leading to significant cost reductions. Furthermore, the integration of robotics and automated quality control systems ensures consistent product quality, vital in industries demanding precision, such as aerospace and automotive. This shift towards smart manufacturing is not just a trend but a necessity for players in this sector to remain competitive and responsive to market needs.

Related Posts

-

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

-

How to Choose the Right Roller Bearing for Optimal Performance and Longevity in Your Machinery

-

Exploring Innovations in Pillow Block Bearing Pullers at the 138th China Import and Export Fair 2025

-

How to Choose the Right Stainless Steel Bearing for Your Application

-

What You Need to Know About 25mm Pillow Block Bearing

-

How to Choose the Right Cast Steel Block Bearing for Your Industrial Needs