Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

As the manufacturing landscape evolves, the significance of Split Pillow Block Bearings is becoming increasingly prominent, particularly in sectors such as automotive, aerospace, and industrial machinery. The 138th Canton Fair 2025 offers a unique platform for industry leaders to showcase innovations and address emerging trends in bearing technology. According to a recent market analysis by Research and Markets, the global bearing market is expected to reach $66.4 billion by 2025, with split pillow block bearings being a substantial contributor to this growth due to their versatile applications and ease of maintenance. This event not only highlights the latest advancements but also provides valuable insights into consumer preferences and technological innovations shaping the future of the industry. Hence, exploring the latest developments surrounding Split Pillow Block Bearings at the fair will be crucial for businesses aiming to stay competitive in a rapidly changing market.

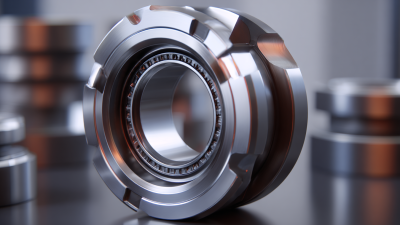

Exploring Innovations in Split Pillow Block Bearings for Enhanced Performance

The 138th Canton Fair in 2025 presents a unique opportunity to delve into the latest innovations in split pillow block bearings, a crucial component in various industrial applications. These advancements promise enhanced performance, efficiency, and longevity. As manufacturers strive to meet increasing demands for durability and reliability, innovations such as improved sealing technologies and advanced materials are becoming more prominent. Such enhancements not only mitigate maintenance costs but also extend the lifespan of the bearings, making them a smart choice for businesses.

When considering upgrades or new installations of split pillow block bearings, look for newer designs that incorporate self-aligning features and vibration-damping capabilities. These technologies can significantly improve machine performance and reduce wear over time. Additionally, pay attention to suppliers who prioritize sustainability; options crafted from eco-friendly materials can minimize the environmental impact while maximizing efficiency.

Tips: Regularly inspect your bearings to identify any signs of wear early on, and don't hesitate to consult with manufacturers about the latest innovations. Investing in quality bearings will yield long-term benefits in terms of operation costs and machinery reliability.

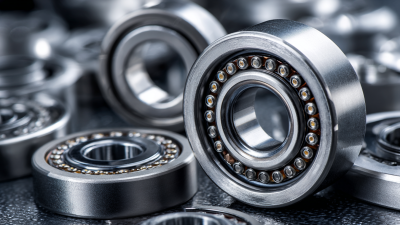

Key Industry Players Showcasing Split Pillow Block Bearings at Canton Fair

As the 138th Canton Fair 2025 approaches, key industry players are gearing up to showcase their latest innovations in split pillow block bearings. These components are crucial in various applications, providing robust support for rotating shafts while minimizing wear and tear. According to a recent market research report by ResearchAndMarkets, the global bearing market is projected to reach USD 120 billion by 2026, with split pillow block bearings being a significant contributor to this growth due to their convenience in maintenance and installation.

Several well-known companies will be present at the fair, highlighting their advanced designs and technologies in split pillow block bearings. For instance, Schaeffler and SKF are expected to present their latest solutions that enhance efficiency and reliability in industrial machinery. Their products often leverage new materials and coatings to improve performance, with some reports indicating potential lifespan increases of up to 30% compared to traditional designs.

**Tips:** When exploring the split pillow block bearings at the fair, consider asking about the latest materials used in their production. Additionally, inquire about the maintenance protocols that can maximize performance and longevity. Lastly, keep an eye on emerging trends such as the integration of IoT technology for predictive maintenance, which is becoming increasingly relevant in industrial applications.

Exploring Split Pillow Block Bearings at the 138th Canton Fair 2025: Industry Insights and Trends

| Bearing Type | Material | Load Capacity (kg) | Operating Temperature (°C) | Market Demand (Units) |

|---|---|---|---|---|

| Standard Split Pillow Block | Cast Iron | 2500 | -20 to 100 | 15000 |

| Stainless Steel Split Block | Stainless Steel | 3000 | -20 to 120 | 8000 |

| High-temperature Split Pillow Block | Aluminum Alloy | 2000 | -30 to 200 | 5000 |

| Corrosion-resistant Split Block | Bronze | 1500 | -10 to 80 | 4000 |

Emerging Trends in Split Pillow Block Bearing Technology for 2025

As we approach the 138th Canton Fair in 2025, the focus on split pillow block bearing technology is becoming increasingly pronounced. With the rise of automation and the need for enhanced performance, industry reports indicate that the global market for pillow block bearings is projected to grow significantly, driven primarily by advancements in material science and engineering. Emerging trends reveal a shift toward more sustainable manufacturing processes, as companies seek to minimize their carbon footprint while improving product efficiency.

Recent insights from Interzum 2025 highlight the importance of innovation in bedding technology, which parallels developments in bearing designs. For instance, the integration of smart materials that offer temperature regulation and durability reflects a broader trend toward multifunctional products. This trend is likely to influence the design and application of split pillow block bearings, as industry leaders strive to enhance operational performance in various sectors, from manufacturing to transportation. Specifically, research indicates that the adoption of technologically advanced bearings can reduce maintenance costs by up to 30%, underscoring the value these innovations bring to the industry in 2025 and beyond.

Sustainability Practices in the Manufacturing of Split Pillow Block Bearings

The manufacturing of split pillow block bearings is increasingly focusing on sustainability, aligning with global industry trends. According to a report by MarketsandMarkets, the bearing market is projected to reach $100 billion by 2025, with a significant portion attributed to eco-friendly manufacturing practices. This shift is driven by rising awareness of environmental impacts and the demand for efficient, long-lasting products. Manufacturers are now prioritizing the use of recyclable materials and adopting energy-efficient processes to minimize their carbon footprint.

Sustainability practices in this sector include using advanced materials that reduce waste and enhance product lifecycle. A recent survey by the Bearing Manufacturers Association highlights that 62% of companies are investing in green technologies to support sustainable development goals. Additionally, manufacturers are exploring ways to optimize supply chains, reducing emissions during transportation and production. As industries transition toward more responsible practices, the emphasis on sustainable split pillow block bearings will likely expand, influencing future innovations and market dynamics.

Exploring Sustainability Practices in Split Pillow Block Bearings Manufacturing

Market Demand and Growth Projections for Split Pillow Block Bearings in 2025

The market for split pillow block bearings is anticipated to experience substantial growth in 2025, driven by increasing demands across various sectors including manufacturing, mining, and agriculture. According to a recent report by Market Research Future, the global bearing market is projected to reach USD 80 billion by 2025, with split pillow block bearings accounting for an increasingly significant portion due to their versatility and ease of maintenance. The rise in automation and advanced machinery in industrial applications is further amplifying this demand, as industries seek reliable components to enhance operational efficiency.

Moreover, the adoption of split pillow block bearings is being fueled by innovations in design and materials, which improve performance and durability. A study by TechSci Research highlights that the Asia-Pacific region is set to lead the market, driven by rapid industrialization and a growing base of manufacturing facilities. With the expected compound annual growth rate (CAGR) of 5.2% from 2020 to 2025 for this segment, manufacturers are urged to invest in advanced technologies to meet this rising need and maintain competitive advantage in the evolving marketplace.